|

|

Only a Few Angles Tomography in Science and Technology Back Ill-Posed Problems in a physical experiment

|

|

||||

|

Presented design professor, Ph.D., Phylonin O.V. in the field of tomography for scientific applications |

||||||

|

|

Tomography system for studying the structure of materials and quality control of products |

|

||||

|

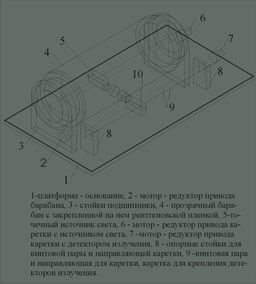

Structural and kinematic few-projection tomography systems for studying the structure of the Solid Materials

Kinematic scheme of electromechanical optical - electronic scanner to read data from X-ray images of large format

Design feature of this scanner is the fact that the studied X-ray film is attached to two end flange motors, rotating synchronously. Sources of light and streak are located on opposite sides of the picture, at a sufficiently high precision manufacture of mechanical components becomes possible to focus the readout beam at a certain layer of the film, which greatly increases the information returns, and further simplifies the transition to kvazi colors.

Kinematic scheme of electromechanical optical - electronic scanner to read the 9 X-ray films - two-dimensional projections of the object

In this scheme, a laser light source and photo detectors are still attached to the plate - the basis, move only translucent and transparent mirrors, this provides an opportunity to increase the scanning speed and reduce the conversion error of the density of blackening in the amplitude of the signal.

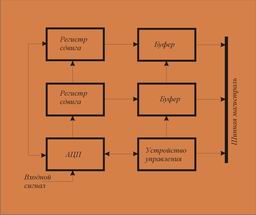

One of the variants of the electromechanical coupling the scanner to a personal computer is shown below:

The developed system for collecting baseline data on this page are interfaced with standard PC through a universal interface board, a block diagram of one of these cards is shown on the right. We deemed it appropriate. For unloading CPUs MS provide such a system buffer devices for intermediate storage.

|

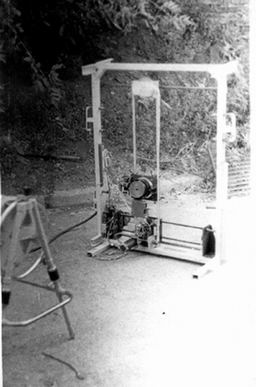

Exterior Systems tomography diagnosis to study the structure of materials, defect detection, imaging one-piece products

Optical-mechanical scanner for reading information from large-format X-rays

This system is designed to read information from X-format 300 X400 mm 2 at a resolution of 0,01 mm, the system is an electromechanical drum-type scanner, a source of light radiation which can serve as low-voltage incandescent, linear discharge lamps of high pressure, laser emitters. Information is derived or small-sized photomultiplier or photodiode array.

A variant reading from different layers of X-rays used in industrial radiography. Manage Settings reading: scanning speed, resolution, dynamic range of the value of the input signal is carried out with a personal computer through a charge conjugation. Scanners of this type are designed to read data from X-ray films used in nondestructive testing, medicine and scientific research.

Optical-mechanical scanner for simultaneous readout from 9 X-rays

Scanner allows you to read X-rays (projection) size (150 x 100) mm2 at a resolution of 100 lines per mm, angular velocity of the drum 1, on / with. His ADC can generate 16, 32 and 64 bit images (in amplitude). Information is read by three parallel focused laser beams (see kinematic scheme), the information recorded by photoelectric multipliers, which have a large dynamic range, power amplifiers, video contains a noise-canceling system.

In the channel video processing of the projections also contain blocks preliminary data processing and filtering. Electrician scanner controlled by a separate microprocessor, which allowed us to obtain sufficiently high performance. To select the desired section in the scanner is turned on an additional monitor with low resolution to track the quality of filtering, the signals observed tomogram in this section of the low dilution, which makes it possible to form an optimal algorithm for reconstruction of the desired section.

|

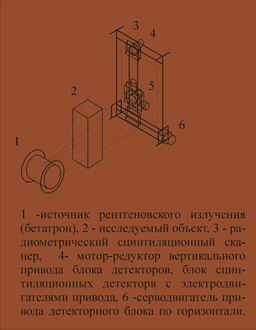

Radiometric scintillation tomography scanner to study the large-sized products

Main technical features: scanning area (800 x 900) mm2, diameter collimator central detector of 6 mm, the velocity of the vertical 0 and 05 m / s velocity in the horizontal (average) 0,01 m / s, the maximum energy of bremsstrahlung recorded block detectors up to 8 MeV, the maximum thickness of radiographic material with an equivalent density of 2.3 g/cm3 to 0, 8 m, the number of two-dimensional projections can be chosen from 6 to 24, scanning parameters can be controlled through a personal computer with which the scanner is connected a separate card interface, the signals from the detectors are fed to the PC via another charge conjugation.

This two-dimensional scanner provides the possibility of using the robot arm to obtain the original two-dimensional projection data in sferotangentsial or cilindrotangentsial geometry.

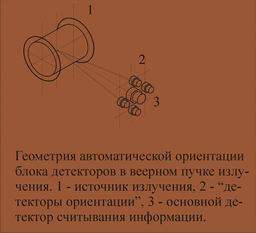

In fan-beam radiation for control of bulky items should automatically orient scintillation detectors in such a way that the axis of the collimator was collinear beam of photons for this purpose in the system contains four detector orientation, see Fig.

Example of layer 3D-reconstruction of the standard steel in reinforced concrete phantom shown in Fig.

3D-reconstruction of the space radiation field intensity of small-sized betatron (energy 6 MeV).

|

||||

|

Kinematic scheme of radiometric scintillation scanner for investigation of large products

Rather simple scheme of the scanner for 3D-tomographic diagnosis of large-sized products. Scanning area for a projection of the order of one square meter, a source of illuminating radiation can serve as a small-sized accelerators - betatron, microtron, linear accelerators ... To implement the geometry of the tomography scan serves as a hydraulic manipulator (not shown).

Since at this volume scanning technique has to use a fan, then the orientation of the collimator central detector is proposed to use four additional detector orientations.

|

Examples of few-projection tomograms of specimens of composite materials obtained by using a scanner to read data from a 9-image projections are shown in the figures below. The upper figure significantly influence the radial artifacts due to insufficient number of interpolated projections. The disadvantages of the image (see lower figure) should include an inefficient interpolate intermediate times in each of the original projection.

|

Of few radiographic tomography for diagnosis of problems of industrial

In the industrial diagnostic radiography is widely used, and I must say that despite the development of alternative methods and means of diagnosis, radiography is still long to hold leading positions in its simplicity, accessibility, high reliability of the information received. The bottleneck here is the introduction of information recorded on X-ray film to a personal computer. To solve this problem a few only X-ray tomography scanner for use in the control of such extended objects as welds, responsible and permanent connection, etc. In these applications, imagers of this type differ only in the parameters of electro-optical systems.

This scanner can operate quite independently, has its own subsystem of the provisional reconstruction, monitors and so on. D. However, better information can be obtained by processing the initial data on multi-processor PC. Size of the scanned film is 300 x 400 mm2, which allows the analysis of such fractures on the same tape to fix the 2, 3 projections. Appearance tomography is shown in the figure. A similar radiographic scanner was designed and built for quality control of welded joints especially responsible products. |

||||

>

Copyright © 2010-2011. All Rights Reserved. Your interactions with this site are in accordance with our statements.